Precision Sealless Pumps Pvt. Ltd.

Accessories

Accessories

Dry Run Protection

Dry Run Protection Is A Low-current Sensing Device Designed To Safeguard Pumps From Cavitation, Which Occurs When Suction Flow Drops To Unsafe Levels. This Protective Device Automatically Shuts Off The Pump To Prevent Damage. Suction Flow

May Decrease Due To:

- Strainer Blockage

- Sudden Closure Of Suction Or Discharge Valves

- Vapor Lock Affecting Suction Flow

- Inadequate Net Positive Suction Head

Thermostat

In Canned Motor Pumps, The Motor Is Cooled By The Pumped Fluid Itself. The Appropriate Insulation Class Is Selected Based On The Fluid Temperature. Sometimes, The Motor Winding Temperature Can Exceed Safe Limits Due To Cooling System Malfunctions. To Prevent Motor Damage, A Thermostat Is Installed At The Winding’s Hot Spot. Typically, This Thermostat Is Of The Closed-contact Type, Set To Trigger And Shut Off The Motor If Temperatures Rise Above A Preset Limit. Thermostats Are A Standard Safety Feature In Canned Motor Pumps.

Bearing

The Description You Provided Seems To Refer To Specific Types Of Bearings Used In Pumps, Particularly Those Designed To Operate Without External Lubrication And To Withstand Harsh Conditions. These bearings are often referred to as “Self-Lubricating Bearings” Or “Self-Lubricated Bushings.” They Are Engineered To Endure Abrasive Fluids And Adverse Conditions Without Requiring Additional Lubrication, Enhancing Their Durability Enhancing Their Durability And Lifespan. The Material Options Mentioned, Such As Carbon Graphite, Silicon Carbide, And Tungsten Carbide, Highlight Their Capability To Withstand Different Types Of Process Fluids And Their Associated Challenges.

Temperature Monitors

Thermowells And Thermocouples Are Integrated Into Pump Constructions To Monitor Fluid Temperature. Thesedevices Enable Automatic Shutdown Of The Pump Assembly If Temperatures Exceed Safe Limits, Thereby Preventing Potential Damage To The Pump.

E-bearing Monitor

The E-bearing Monitor Operates On The Principle Of Induced Voltage. The Current Flowing Through The Stator Winding Generates A Magnetic Field In The Ebm Coils. Additionally, The Rotor Generates Its Own Magnetic Field As A Result Of The Currents Induced Within It. These Induced Currents In The Rotor Arise From The Interaction With The Stator’s Magnetic Field, Thereby Contributing To The Overall Magnetic Field In The System.

Inducers

This model has a chamber that allows for self priming. It is particularly suitable for pumping from underground tanks and applications with entrained gases.

Automatic Thrust Balance

This Automatic Thrust Balancing Mechanism Likelyuses Hydrodynamic Principles To Achieve A Selfstanding Impeller Position, Which Helps Inextending The Life Of Bearings. It’s A Commonfeature In High-efficiency Pumps And Rotatingequipment To Ensure Reliability And Longevity.

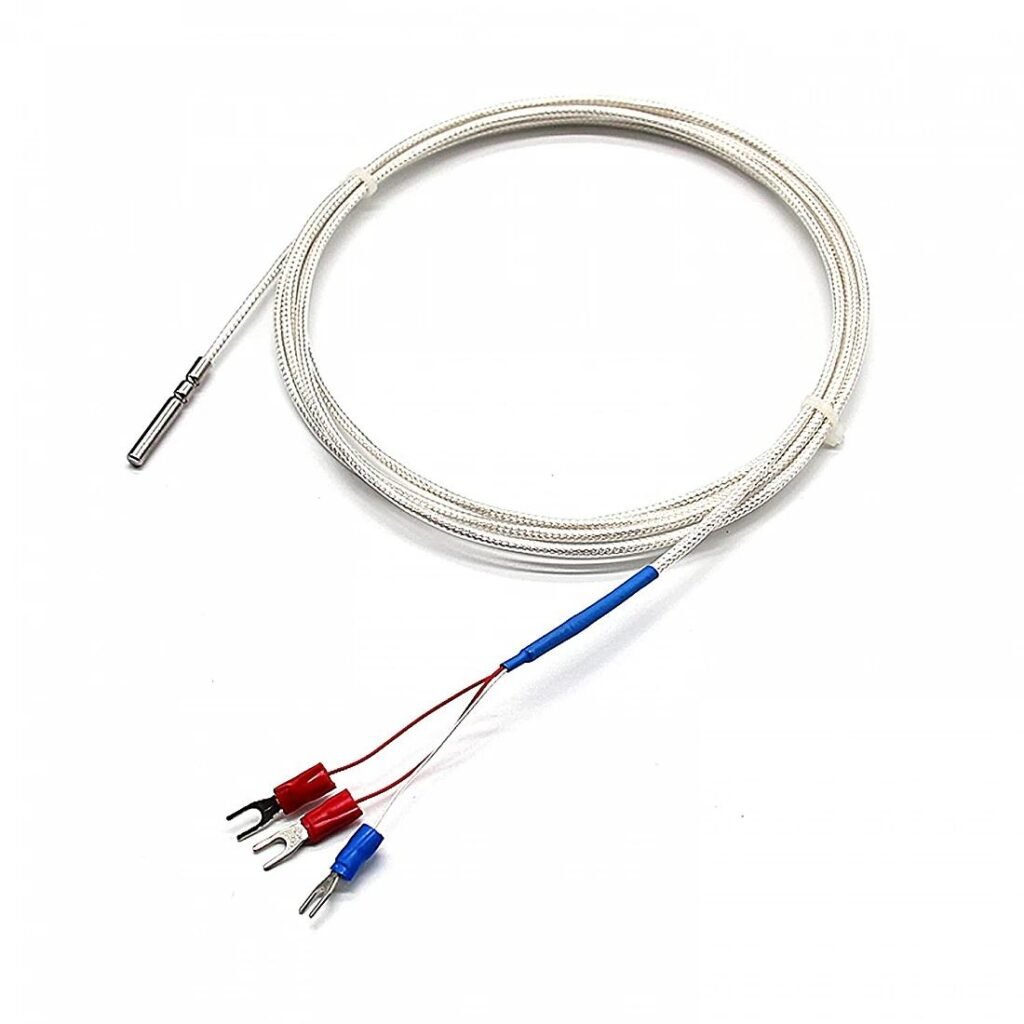

Resistance Temperature Detector

A PT100 is the most common type of Resistance Temperature Detector (RTD). The PT100 has a resistance of 100 Ohms at 0°C and 138.5 Ohms at 100°C. PT100s are a common choice for measuring temperature in industrial processes and laboratories. They are a popular choice due to their stability, accuracy and repeatability.

Bearing Monitor

The Bearing Monitor addresses a critical issue common to all Sealless Pumps by detecting bearing wear, enabling routine maintenance before significant motor damage happens. It monitors bearing wear in both axial and radial directions. This unique design features a gas-filled gauge, mounted on the rear bearing housing. The monitor’s contact tip fits into a cavity in the shaft’s end nut, and the clearance between them indicates the maximum allowable bearing wear.