Precision Sealless Pumps Pvt. Ltd.

Canned Motor Pump

Canned Motor Pump

Canned Motor Pump

The stator is canned in the air gap, confining the liquid in the rotor chamber. The pump liquid circulates through the rotor chamber, cooling the motor, and lubricating the slide bearings that support the rotor. The casing of the chamber forms a sealless enclosure that confines the liquid without any precision sealing

Sealless Canned Motor Pump

The Sealless Canned Motor Pump is a centrifugal pump which eliminates the requirement of a mechanical seal or other sealing device due to the presence of hermetically sealed electric motor mounted on single shaft ensuring no leakage.

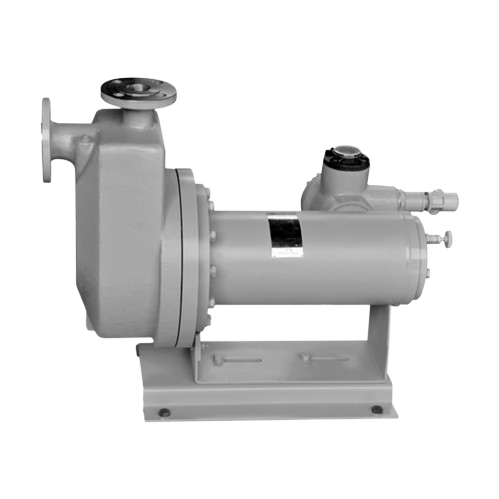

Self-Priming Canned Motor Pump

This model has a chamber that allows for self priming. It is particularly suitable for pumping from underground tanks and applications with entrained gases.

Ammonia Liquid Canned Motor Pump

Ammonia pump is designed for the hardest of working conditions. Known to be durable, leak proof and resistant to corrosion, you can get any of the pumps in standard as well as customized options. pumps for transferring and recirculation ammonia are high end, zero-emissions solutions to a number of industry sectors that include various refrigeration plant, ice plant, frozen-food processing plant among many others.

Slurry Sealless Canned Motor Pump

For moving fluids with solid content, slurry handling canned motor pumps include an internal mechanical seal that prevents the entry of solids into the rotor chamber. Available with or without a gas chamber, these high-performing, low-maintenance canned motor pumps are recognized worldwide as both reliable and robust.

Reverse Circulation Canned Pump

This canned motor pump handles highly volatile liquids such as liquefied gas and low boiling point liquids.Circulating fluid that lubricates bearings and cools the motor is returned to the suction tank vapor zone, ensuring stable operation without cavitation and vapor lock issues.

High Temperature Canned Motor Pump

Excellent for high temperature applications where no cooling water is available. This model uses non-organic insulation materials allowing for higher motor operating temperatures.The pumps are designed for high temperature, The pump and motor are separated thermally by an adaptor which prevents heat transfer from the pump to motor area. In these pumps an independent circulating system with cooling jacket and heat exchanger is provided. Circulation is effected by the auxiliary impeller located at the front end of the rotor chamber.

Multi stage canned motor pump

Multistage pumps are designed for high head, low flow duties. For pumping to high discharge pressures, increased heads are achieved by running the fluid from discharge of one impeller to the suction of the succeeding one.Tailored for applications requiring high head and low flow rates, our Multistage Pumps are optimized for efficiency in diverse industrial settings.Ideal for scenarios demanding elevated discharge pressures, these pumps deliver exceptional performance by utilizing multiple impellers in succession. Versatile and robust, our pumps serve as effective multi-stage booster pumps, ensuring reliable and consistent fluid transfer in challenging environments.

Vertical canned motor pump

vertical canned motor pumps are preferred for all liquids containing gas or vapours. The gas or vapour settled in the pump must find there way out even when the pump is stopped. The heat in the motor is often high enough to vaporize all the liquid in the pump and the vapour may occupy all the space in the pump & motor. This will cause quick bearing wear on restart of the pump, precision vertical canned pump avoids this by ensuring gas venting at the top of pump. The vertical construction also minimizes radial load on bearings by transferring load to axial direction and then floating the entire rotor via hydraulic thrust balancing.